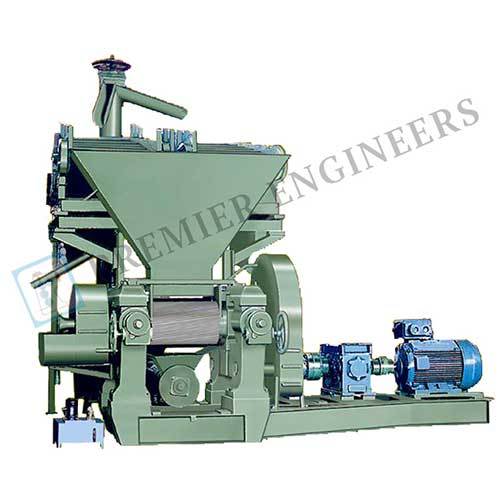

Rubber Strainer Machine

Price 30000 INR/ Unit

MOQ : 1 , , Unit

Rubber Strainer Machine Specification

- Type

- Rubber Strainer Machine

- Material

- High-grade Alloy Steel

- Capacity

- 300 - 600 kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic / Fully Automatic

- Control System

- PLC Based Panel

- Cooling System

- Water Cooled

- Rolller Speed

- 40 - 65 RPM

- Max. Diameter

- 250 mm

- Power Consumption

- 22 - 75 kW

- Voltage

- 380 V / 415 V (Three Phase)

- Weight

- 3500 kg approx.

- Dimension (L*W*H)

- 3200 mm x 1200 mm x 1600 mm

- Feed Opening

- 200 x 120 mm

- Surface Finish

- Powder Coated

- Application

- Filtering and removing impurities from raw rubber

- Driven Type

- Electric

- Noise Level

- 85 dB

- Roller Material

- Alloy Steel

- Safety Features

- Emergency Stop, Overload Protection

- Lubrication System

- Automatic

- Production Line Compatibility

- Yes

- Heating System

- Electric Heater

Rubber Strainer Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 15 Days

About Rubber Strainer Machine

Get an immaculate solution for rubber processing with our Rubber Strainer Machinea hot deal and must-have for modern manufacturing! Engineered with high-grade alloy steel rollers and a polished, powder-coated surface, this machine delivers sensational performance in filtering and removing impurities from raw rubber. Its electric-driven design offers power consumption from 22 to 75 kW, with advanced features including PLC-based control panels, automatic lubrication, and robust safety systems. Compatible with production lines, this pristine, 3500 kg machine is perfect for exporters, manufacturers, and suppliers across India.

Surface Applications, Features, and Users

Ideal for rubber manufacturing and processing plants, the Rubber Strainer Machine excels in filtering and removing impurities from raw rubber with precision. Its sensational design includes a water-cooled system, emergency stop, and overload protection, making it suitable for varied operational settings. This must-have equipment is widely used by manufacturers, exporters, and suppliers for its reliable performance, semi-automatic to fully automatic control, and compatibility with modern production lines, ensuring product quality and operational efficiency every time.

Domestic Market, Certifications, and Sample Availability

Our Rubber Strainer Machine enjoys a strong presence in the main domestic market as well as the export market with trusted certifications confirming its quality. Customers can request a quotation for tailored solutions, and timely drop-off is assured for large or sample orders. Certified manufacturing processes underscore every delivery, making samples available for evaluation prior to large-scale purchasingan excellent opportunity for those considering expansion into international or new domestic markets.

Surface Applications, Features, and Users

Ideal for rubber manufacturing and processing plants, the Rubber Strainer Machine excels in filtering and removing impurities from raw rubber with precision. Its sensational design includes a water-cooled system, emergency stop, and overload protection, making it suitable for varied operational settings. This must-have equipment is widely used by manufacturers, exporters, and suppliers for its reliable performance, semi-automatic to fully automatic control, and compatibility with modern production lines, ensuring product quality and operational efficiency every time.

Domestic Market, Certifications, and Sample Availability

Our Rubber Strainer Machine enjoys a strong presence in the main domestic market as well as the export market with trusted certifications confirming its quality. Customers can request a quotation for tailored solutions, and timely drop-off is assured for large or sample orders. Certified manufacturing processes underscore every delivery, making samples available for evaluation prior to large-scale purchasingan excellent opportunity for those considering expansion into international or new domestic markets.

FAQs of Rubber Strainer Machine:

Q: How does the Rubber Strainer Machine benefit rubber manufacturing processes?

A: The machine efficiently filters and removes impurities from raw rubber, improving the final products quality while ensuring consistent and reliable-output suitable for various manufacturing needs.Q: What features make this machine a must-have for factories?

A: With automatic lubrication, PLC-based control panels, emergency stop, overload protection, and polished powder-coated surfaces, the machine offers safety, durability, and user-friendly operation essential for high-demand environments.Q: Where can this machine be used?

A: It is suitable for application in both small- and large-scale rubber manufacturing plants, and is compatible with diverse production lines across domestic and export markets.Q: What is the process for obtaining a quotation or sample?

A: Interested customers can request a quotation by contacting the supplier directly. Sample units can be made available to assess performance before placing large orders, with smooth drop-off and support provided.Q: When should you consider upgrading to a fully automatic model?

A: Upgrading is recommended when operational volume increases or when greater automation is needed to enhance production speed, consistency, and worker safety within a growing manufacturing environment.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Reclaim Rubber Machine Category

Rubber Debeader Machine

Price 300000 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic Grade : SemiAutomatic

Material : Mild Steel

Type : Rubber Debeader Machine

Voltage : 380V / 440V

Rubber Refiner Machine

Price 4000000 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : SemiAutomatic

Material : Graded Steel Casting

Type : Rubber Refiner Machine

Voltage : Upto 440 Volt (v)

Rubber Grinder Machine

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Mild Steel

Type : Rubber Grinder Machine

Voltage : 220 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS